We’ve been conducting some tests with the this old school beast and we are suitably impressed. The giant magnet and large 4″ voice coil give great efficiency (111dB) and loads of power handling (150W). Just look how this giant compares to the 1″ B&C DE250:

The question most people have when looking at a large compression driver like this is will it play high enough? We’ve run some tests with the P.Audio horns PH.2380 (90×40) and PH.2723 (60×40). Please excuse the coloured lighting!

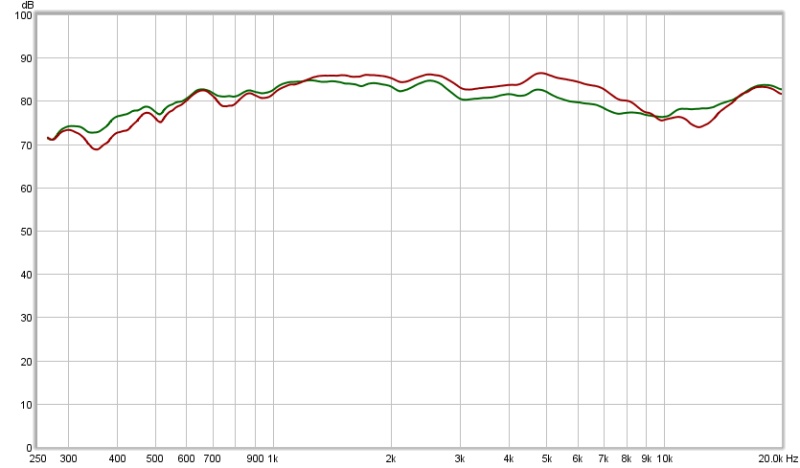

We took some rough measurements with the two horn flares (SPL not calibrated and measurements are subject to room reflections).

This monster compression driver can certainly cover the entire high frequency spectrum from 1KHz to 20KHz. For certain music styles there is always the option of adding another device such as a super-tweeter to improve the response 6KHz upwards. This may be especially beneficial on certain horn flares such as the PH.2723 and fits with what you would expect of designs using the JBL 2445 or other large format compression drivers.