Beyma Unveils Next-Gen Compression Drivers: Limitless Audio Possibilities!

Beyma, the leading name in audio innovation, is proud to introduce its latest generation of compression drivers, pushing the boundaries of sound reproduction to unprecedented heights. This cutting-edge series encompasses 12 new models, offering a versatile selection that caters to a wide range of audio needs. Let’s delve into the key features and technologies that make these compression drivers stand out from the crowd.

Introducing the Models:

- CD314: Throat Diameter – 1.4 in | Voice Coil Diameter – 3 in

- CD2514: Throat Diameter – 1.4 in | Voice Coil Diameter – 2.5 in

- CD171: Throat Diameter – 1 in | Voice Coil Diameter – 1.75 in

- CD151: Throat Diameter – 1 in | Voice Coil Diameter – 1.5 in

Precise Sound Tailoring:

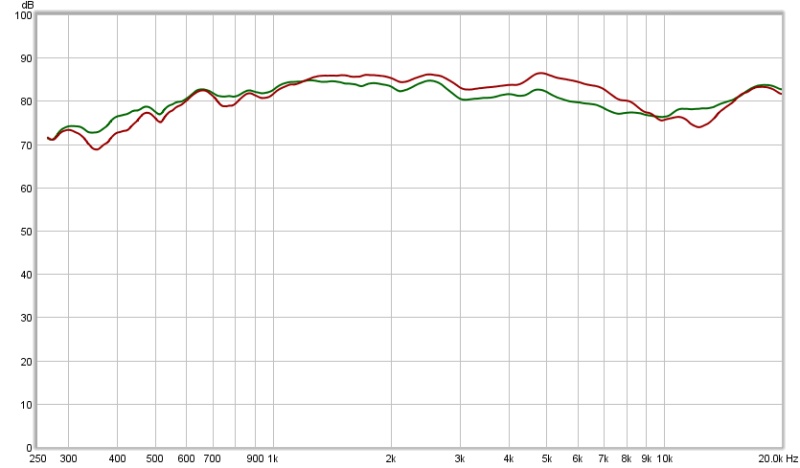

One of the standout features of Beyma’s new compression drivers is the ability to tailor the sound to perfection. With three diaphragm material options – Titanium, High Temperature Polymer, and Advanced Polyester – users can achieve distinct SPL responses, timbre, and sonic properties. This flexibility empowers system designers to create audio experiences that precisely match their acoustic targets and application requirements.

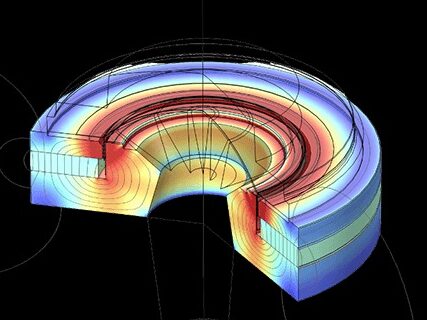

VPEQ Technology: Equalization of the Frequency Response

To combat inherent frequency response irregularities caused by transmission channels’ eigenmodes, Beyma’s Research and Development team has developed VPEQ technology. By carefully varying the duct shape, the system’s frequency response is linearized, resulting in a remarkable improvement in sound transfer. The organic shape, designed according to different mathematical functions, ensures a significant variation in sound pressure level for calculated frequencies, leading to a superior transient response. VPEQ optimizes the compression driver’s performance, enhancing the overall sound quality.

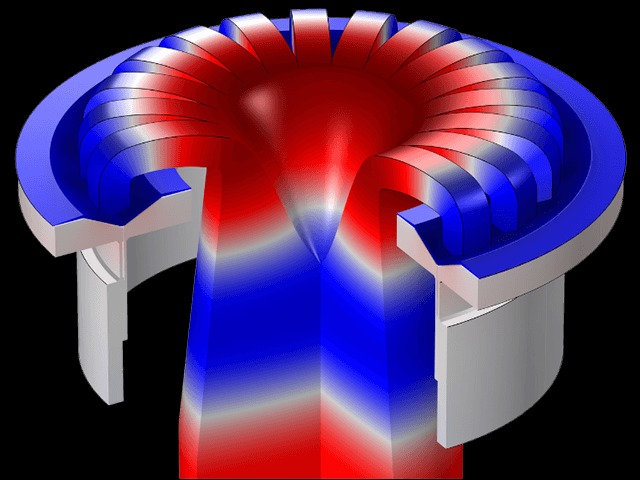

DEPLOCEX Technology: Improved Thermal Dissipation

For audio professionals seeking exceptional performance, thermal dissipation is a critical aspect. Traditional designs often face challenges in handling high SPLs while effectively dissipating heat. With DEPLOCEX technology, Beyma revolutionizes thermal dissipation in compression drivers. By maximizing the surface area of the coil and magnetic gap, the configuration enhances heat dissipation through radiation while maintaining the necessary Bl and final SPL. This groundbreaking approach reduces the coil’s temperature by up to 30%, minimizing the impact of power compression and delivering high-frequency drivers that are more than 15% more powerful. DEPLOCEX ensures reliable and consistent performance even under demanding conditions.

Unleash Your Creativity:

With the combination of VPEQ and DEPLOCEX technologies, Beyma’s new compression drivers offer unparalleled audio design possibilities. Musicians, sound engineers, and audio enthusiasts can now achieve extraordinary sound precision and clarity in their setups. Whether you’re working on professional sound systems, studio monitors, or any high-fidelity audio applications, Beyma’s next-gen compression drivers are your gateway to limitless audio possibilities.

Experience the future of audio technology with Beyma’s groundbreaking compression drivers. Upgrade your sound system today and explore the world of sound perfection.

Explore the New Compression Drivers

CD-314Nd with Titanium Diaphragm and Neodynium Magnet

CD-314Fe with Titanium Diaphragm and Ferrite Magnet

CD-2514Nd/Ti with Titanium Diaphragm and Neodymium Magnet

CD-2514Fe/Ti with Titanium Diapragm and Ferrite Magnet

CD-2514Nd/Pk with High Temperature Polymer Diaphragm and Neo Magnet

CD-2514Fe/Pk with High Temperature Polymer Diaphragm and Ferrite Magnet

CD-2514Nd/Pt with Advanced Polyester Diaphragm and Neo Magnet

CD-2514Fe/Pt with Advanced Polyester Diaphragm and Ferrite Magnet

CD-151Fe/Pt with Advanced Polyester Diaphragm and Ferrite Magnet

CD-151Fe/Pk with High Temperature Polymer Diaphragm and Ferrite Magnet

CD-171FE/Pt with Advanced Polyester Diaphragm and Ferrite Magnet

CD-171Fe/Pk with High Temperature Polymer Diaphragm and Ferrite Magnet